Product Description

V-BAND CLAMP

V-band clamps can be used to hold most flanged joints together.

How V-Band Clamps Work

"V-band clamps have proven themselves in racing applications from the Indianapolis 500 to Bonneville land speed cars becoming the preferred connection for many turbo-housings. They are an excellent choice for any exhaust or intake system.

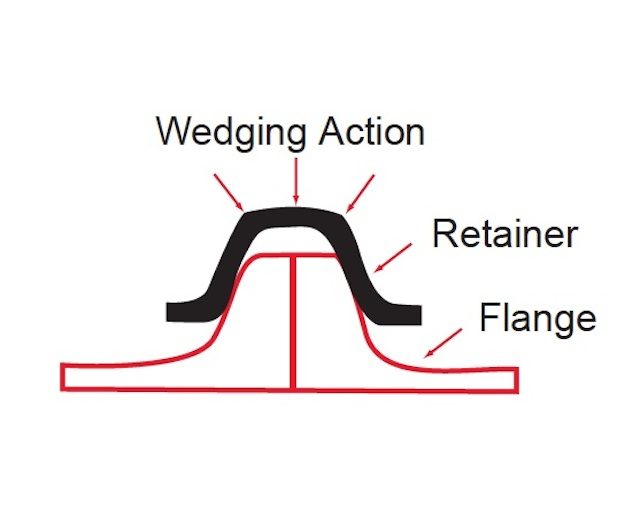

While they come in many different configurations and styles, their primary job is to join tubing, piping and other enclosures. A cross-view of the flange joint shows how the portion of the coupling that wedges the flanges together in a leakproof seal. The strength of the coupling is determined partly by the retainer thickness, the shape of the flange and the material.

|

|

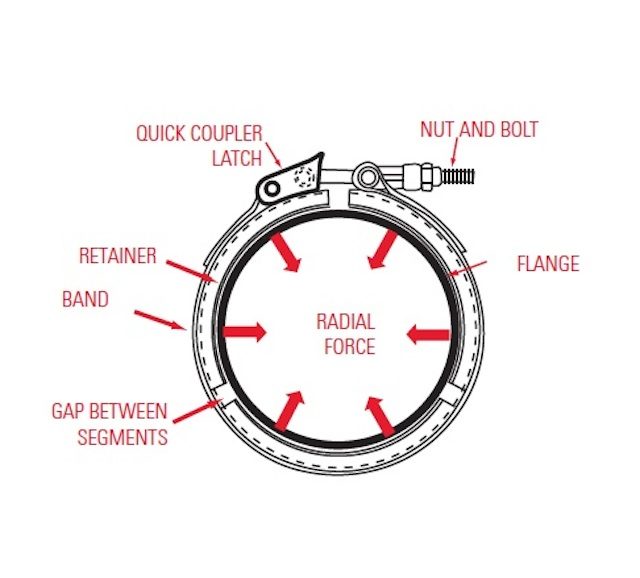

| This cross view of the coupling shows how the clamping force is applied in a wedging action by the clamp's 'V' design. | As torque is applied to the fastening nut, radial force is applied evenly around the coupling's flange. |

- As torque is applied to the nut of the coupling, the retainer applies an inward radial force compressing the flange together. Unlike bolted flanges, the retainer applies a uniform and equal closing force around the entire circumference of the flange during and after tightening.

- Once tightened, friction between the flanges and V-retainer actually helps reduce the load on the bolt and clamp.

- These clamps can be used to hold together virtually any flanged joint. Common applications range from light to heavy duty and include diesel engines, turbochargers, pumps, filter vessels, tubing and countless other flanged items."

Engine labs

US Dollars

US Dollars

Canadian Dollar

Canadian Dollar

Australian Dollar

Australian Dollar

New Zealand Dollar

New Zealand Dollar

Euro

Euro